Over the years I have collected quite a few model kits.

Most kits I have are injection moulded plastic model kits. Apart from that I have several white metal kits and some resin kits as well as resin transkits.

Reason I'm starting this blog entry is the fact that I was completely blown away by the quality of a transkit I purchased from the ZoomOn pro modeling team earlier this year.

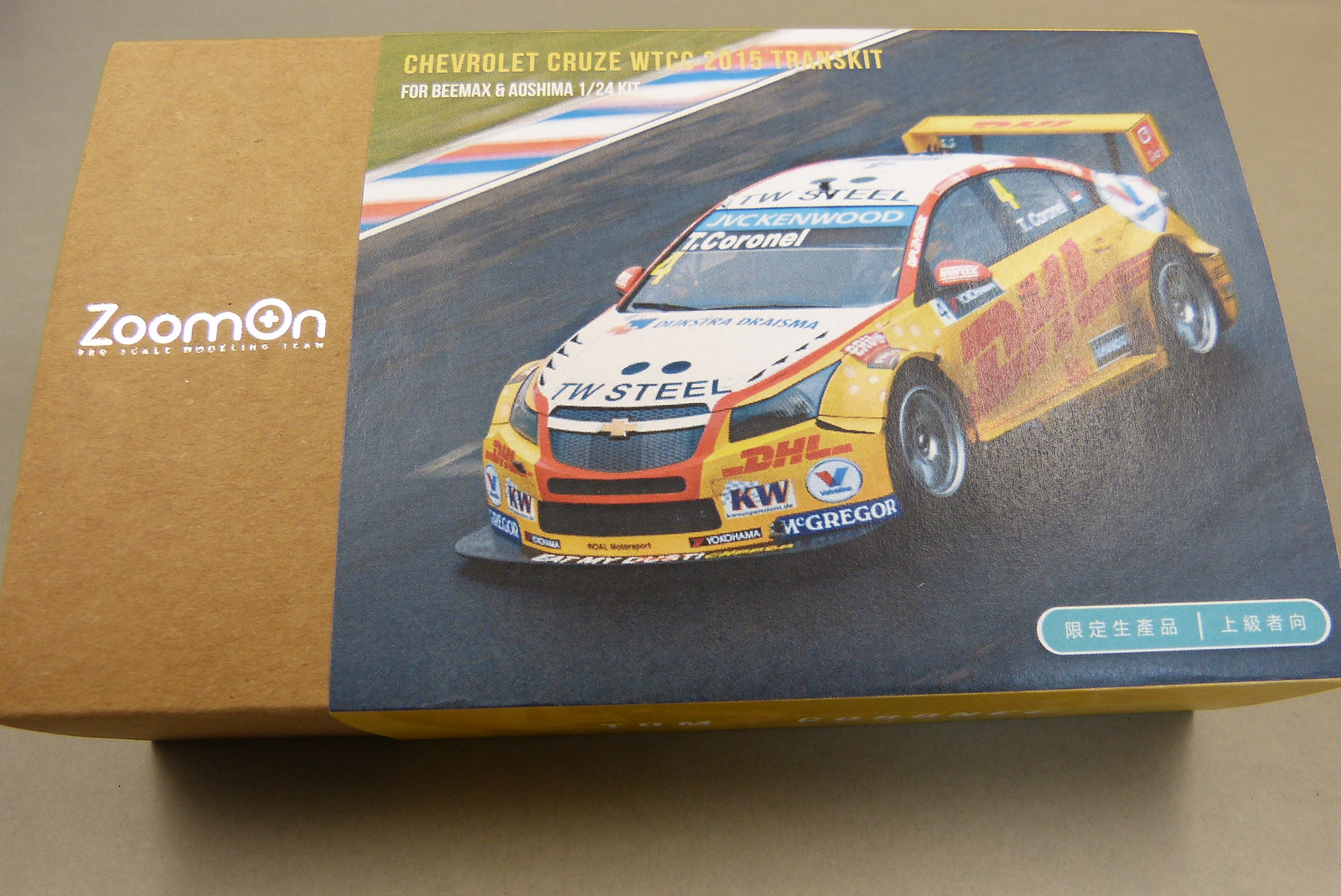

Just look at the impeccable presentation of the transkit in the first place:

Not many companies can top this. And it doesn't stop there.

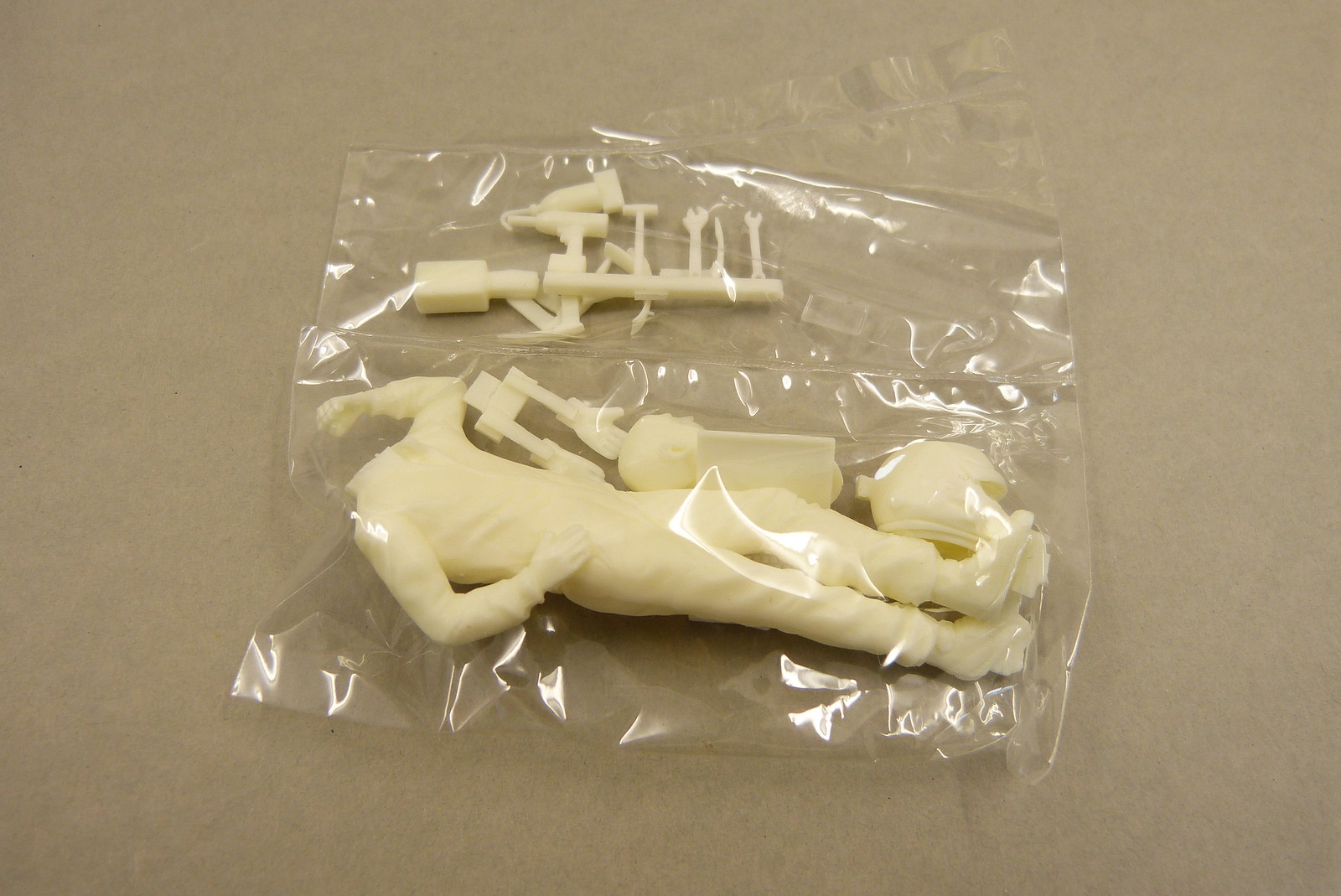

The quality of the parts is unbelievable. No flash, no skins, no casting stubs or blocks. Hardly any clean up necessary.

The wheels are a great example of the casting quality. As are the thin walls on the new body parts.

If I didn't know this was resin I'd say these parts are injection moulded...

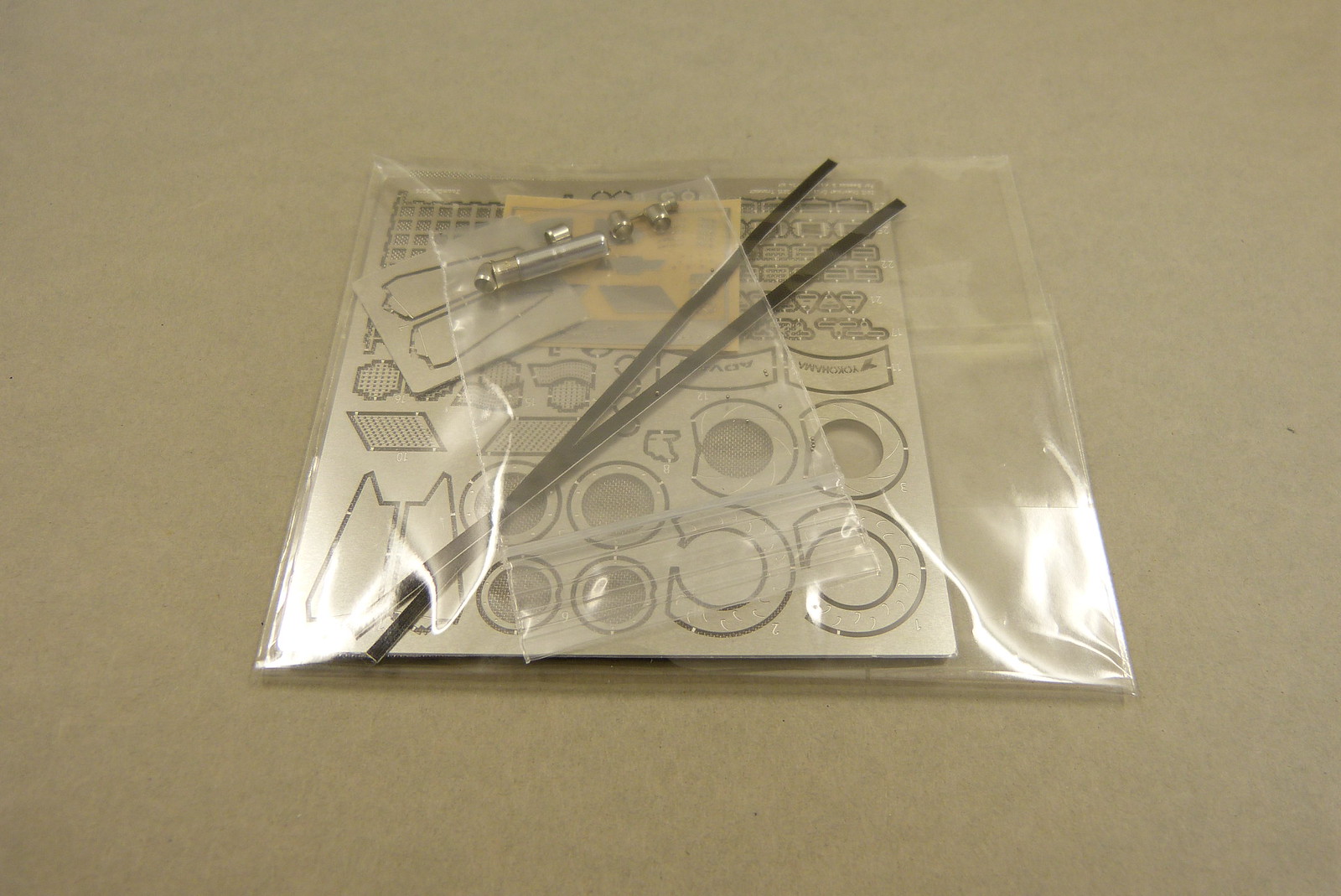

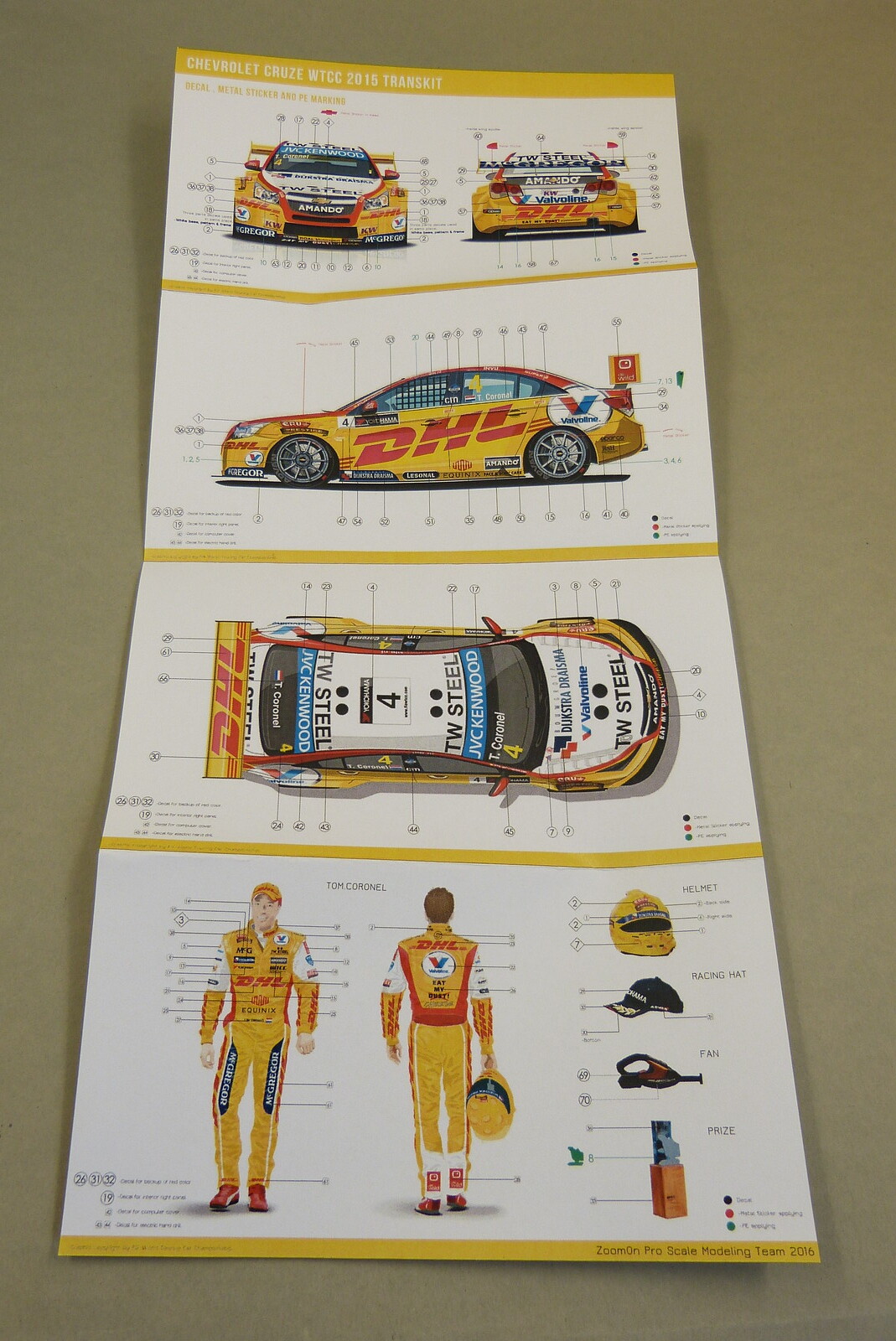

Apart from the resin components there's a quite complete sheet of photo etched parts included as well as several very comprehensive decal sheets.

And to top it all off, there's also a Tom Coronel figure included. Truly outstanding stuff.

What a difference compared to some other manufacturers.

Several resin (trans)kits in my collection are of such bad quality that it's almost an insult having had to pay for these. Notably kits from Eastern Europe or Brazil are really bad in detail and quality...

One kit I recently acquired really stands out from these (in a bad way, that is). Apart from the shoddy detail and so-so quality it had also a really strong smell to it. Even weeks after receiving the kit (and leaving it to gas out in the open air) the smell was still present.

Still, I'd have bought it again, as it depicts a rally car I otherwise wasn't able to build...

Anyway, I'm looking forward to getting started on the transkit from ZoomOn to see if it builds as good as it looks.

So keep checking this blog to see how things are going when I start this kit shortly.

Most kits I have are injection moulded plastic model kits. Apart from that I have several white metal kits and some resin kits as well as resin transkits.

Reason I'm starting this blog entry is the fact that I was completely blown away by the quality of a transkit I purchased from the ZoomOn pro modeling team earlier this year.

Just look at the impeccable presentation of the transkit in the first place:

Not many companies can top this. And it doesn't stop there.

The quality of the parts is unbelievable. No flash, no skins, no casting stubs or blocks. Hardly any clean up necessary.

The wheels are a great example of the casting quality. As are the thin walls on the new body parts.

If I didn't know this was resin I'd say these parts are injection moulded...

Apart from the resin components there's a quite complete sheet of photo etched parts included as well as several very comprehensive decal sheets.

And to top it all off, there's also a Tom Coronel figure included. Truly outstanding stuff.

What a difference compared to some other manufacturers.

Several resin (trans)kits in my collection are of such bad quality that it's almost an insult having had to pay for these. Notably kits from Eastern Europe or Brazil are really bad in detail and quality...

One kit I recently acquired really stands out from these (in a bad way, that is). Apart from the shoddy detail and so-so quality it had also a really strong smell to it. Even weeks after receiving the kit (and leaving it to gas out in the open air) the smell was still present.

Still, I'd have bought it again, as it depicts a rally car I otherwise wasn't able to build...

Anyway, I'm looking forward to getting started on the transkit from ZoomOn to see if it builds as good as it looks.

So keep checking this blog to see how things are going when I start this kit shortly.

Comments

Post a Comment