The Story:

After two unsuccessful years at Lotus, Piquet had signed a contract with Benetton at the end of 1989. After a (according to some people surprisingly) successful 1990, with 2 wins in the last 2 races of the season, Piquet was offered a contract for 1991 by Benetton.

The car I'm going to build, the B190B, ran for the first 2 GP's of 1991 while waiting for the John Barnard drawn B191.

The B190B was in fact more or less the same car as Benetton had used the previous year. Only the livery was changed.

Although the car wasn't new, it still was relatively successfull during those first GP's of 1991. Nelson Piquet scored a nice third and fifth place during those 2 GP's.

The Project:

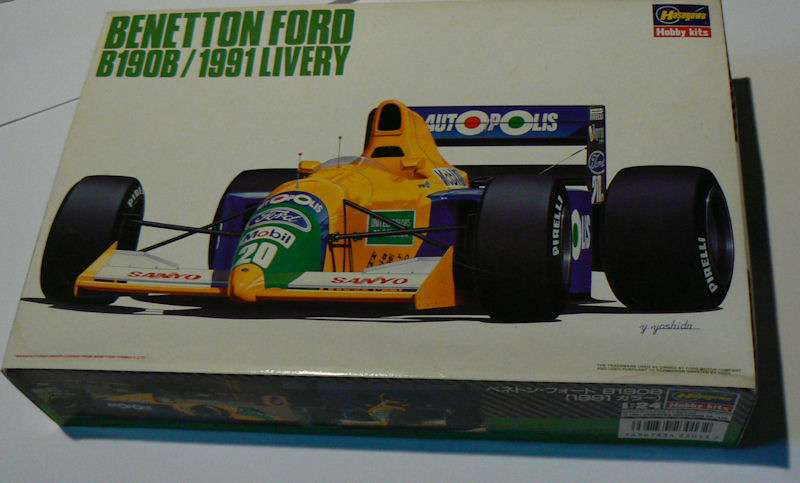

This kit is the fifth project I'm taking on since restarting this hobby.

It will be the first Hasegawa kit I'll be building. And on top of that, it will also be the first F1 kit I'm building in the "unholy" 1/24 scale.

This build will be the second build for my Nelson Piquet collection.

The Kit:

About The Kit:

All the previous F1 kits that I've build have been from Tamiya. So I was a bit curious about the quality of the parts and the fitment of the parts compared to Tamiya.

And I must admit, I am evenly disappointed and surprised by the quality.

Surprised, pleased may be a better word, I was concerning the quality of the monocoque and engine cover. Looks very nice. Good quality. A nice touch is the fact that the borders for the different colours are marked with a slightly raised rib on the body, making masking for the paintjob very easy. Well thought out.

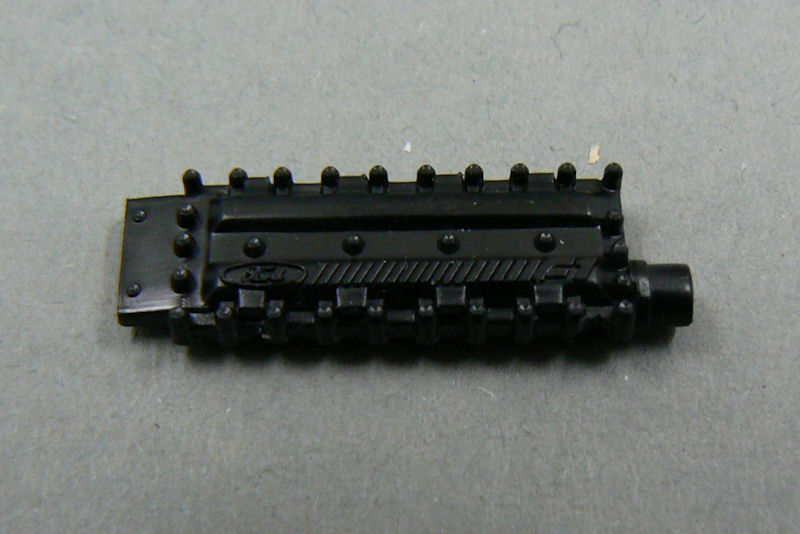

Pleased also with the quality of the valve covers for example (left picture, below). Lots of detail. In my opinion one of the best parts of this kit.

As I already mentioned, other parts of this kit where quite a let down, considering the quality of some of the other parts in this kit.

Especially the several radiators in this kit are not that good. The pattern on the radiators is very faint, and on almost all of them a very prominent ejectorpin mark is present on the part.

Ejectorpin marks are also very visible on the parts for the front and rear wings. And the crap-de-la-crap of this kit must be the front brake cooling ducts. A giant sink mark present on a very visible location.

Almost unbelievable that Hasegawa managed to combine such well thought out and very detailed parts with some very crap ones...

But hey, that's the challenge for the model builder, right ? And anyway, not that big a drama. All those parts I mentioned can be repaired quite easily. It's only a shame that this extra work should be necessary in the first place, because in my opinion this could have been avoided by Hasegawa.

Anyway, enough complaining, on to the actual build report !

Start of the build

The start of the project isn't very spectacular.

After studying the manual I decided to glue together several parts that will be the same colour.

Hasegawa has decided to split the nosecone, airbox and rollbar lengthwise. Looking at Tamiya kits from the same era, I think that this could have been done differently. I do know that for injection molding the solution from Hasegawa is the easiest one. Only setback is that is means more work for me to get rid of the joint lines. But it's not something that can't be done, so it's not such a big deal. Just one of those small things that make you realise what makes Tamiya so good...

I also did a bit of testfitting how the monocoque and engine cover would fit to the bottom of the car. Looks promising, although you might think otherwise, when looking at the picture to the right (below). I think it looks promising.

After two unsuccessful years at Lotus, Piquet had signed a contract with Benetton at the end of 1989. After a (according to some people surprisingly) successful 1990, with 2 wins in the last 2 races of the season, Piquet was offered a contract for 1991 by Benetton.

The car I'm going to build, the B190B, ran for the first 2 GP's of 1991 while waiting for the John Barnard drawn B191.

The B190B was in fact more or less the same car as Benetton had used the previous year. Only the livery was changed.

Although the car wasn't new, it still was relatively successfull during those first GP's of 1991. Nelson Piquet scored a nice third and fifth place during those 2 GP's.

The Project:

This kit is the fifth project I'm taking on since restarting this hobby.

It will be the first Hasegawa kit I'll be building. And on top of that, it will also be the first F1 kit I'm building in the "unholy" 1/24 scale.

This build will be the second build for my Nelson Piquet collection.

The Kit:

About The Kit:

All the previous F1 kits that I've build have been from Tamiya. So I was a bit curious about the quality of the parts and the fitment of the parts compared to Tamiya.

And I must admit, I am evenly disappointed and surprised by the quality.

Surprised, pleased may be a better word, I was concerning the quality of the monocoque and engine cover. Looks very nice. Good quality. A nice touch is the fact that the borders for the different colours are marked with a slightly raised rib on the body, making masking for the paintjob very easy. Well thought out.

Pleased also with the quality of the valve covers for example (left picture, below). Lots of detail. In my opinion one of the best parts of this kit.

As I already mentioned, other parts of this kit where quite a let down, considering the quality of some of the other parts in this kit.

Especially the several radiators in this kit are not that good. The pattern on the radiators is very faint, and on almost all of them a very prominent ejectorpin mark is present on the part.

Ejectorpin marks are also very visible on the parts for the front and rear wings. And the crap-de-la-crap of this kit must be the front brake cooling ducts. A giant sink mark present on a very visible location.

Almost unbelievable that Hasegawa managed to combine such well thought out and very detailed parts with some very crap ones...

But hey, that's the challenge for the model builder, right ? And anyway, not that big a drama. All those parts I mentioned can be repaired quite easily. It's only a shame that this extra work should be necessary in the first place, because in my opinion this could have been avoided by Hasegawa.

Anyway, enough complaining, on to the actual build report !

Start of the build

The start of the project isn't very spectacular.

After studying the manual I decided to glue together several parts that will be the same colour.

Hasegawa has decided to split the nosecone, airbox and rollbar lengthwise. Looking at Tamiya kits from the same era, I think that this could have been done differently. I do know that for injection molding the solution from Hasegawa is the easiest one. Only setback is that is means more work for me to get rid of the joint lines. But it's not something that can't be done, so it's not such a big deal. Just one of those small things that make you realise what makes Tamiya so good...

I also did a bit of testfitting how the monocoque and engine cover would fit to the bottom of the car. Looks promising, although you might think otherwise, when looking at the picture to the right (below). I think it looks promising.

Apart from the above there is not much to be shown yet.

Comments

Post a Comment